The Company

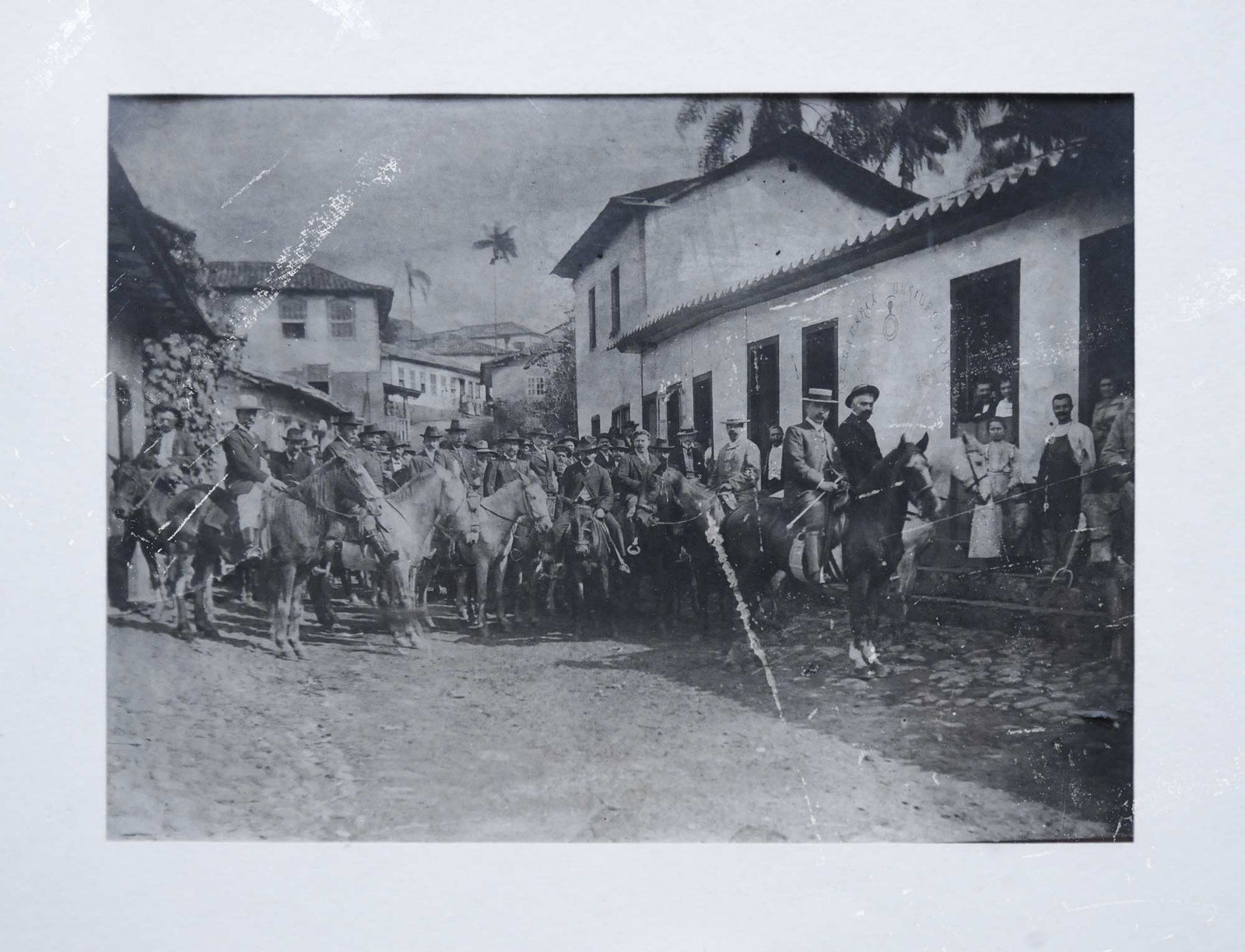

Our family, like many other families in the Dolomites, emigrated to Latin America in the late 1800s. Our great-grandparents lived for years in Minas Gerais, Brazil. When they returned to live here in Presson, they brought with them, in a jar that we still treasure today, some of the coffee beans that were grown so far from our Val di Sole. Despite leaving Brazil, they never lost that invisible thread that connected them to the land of coffee, and they soon opened a roastery with a shop and bar.

More than a century later, this activity seemed like a thing of the past. Until three generations later we decided to rediscover our origins.

With our blends, produced according to artisanal methods that require patience and care, we demonstrate that the “old-fashioned way coffee” is still being made, and it is all to be tasted.

Where the Name Marnei Comes From

Marnei is not our real surname, but the name by which our family was known in the small village of Presson. Since, as is often the case in the mountains, there were many families with the same surname, to each one was given a nickname: we were the Marneis.

Unfortunately, the meaning of this nickname has been lost over time, but nonetheless we felt the urge to choose it for our roastery: it a daily reminder of our origins and of the commitment to carry on a job that is part of our history.

Our Logo: The Alpine Chough

The alpine chough is a typical bird that can be seen in the mountains: just like us, it loves to live high up in the mountains, among pastures and rocky faces. That is why we decided to adopt it within our logo. “Our chough” has something unique: its wings come together to shape a coffee bean.

In Production

The heart of the roastery is a state-of-the-art Probat rotary drum roaster.

Artisanal drum roasting requires longer roasting times, but it guarantees a sweeter, more aromatic, and digestible coffee. Its precise temperature control allows us to create, manage and customize the individual roasting curves to fully develop the potential of each individual batch of coffee.

We process a maximum of 10 kg of raw material per roasting cycle to control heat transfer to the bean throughout the entire process. Combining the art of gentle roasting with the best existing technology allows us to fully manage Strecker synthesis, the Maillard reaction and the caramelisation of sugars.

After reaching the optimal roasting point, the coffee beans are cooled exclusively with air to preserve their stability and aroma, as well as their ability to resist oxidation.

Attention to the Environment

Recyclable Packaging

Our packaging is 100% recyclable and equipped with a one-way valve and a zipper seal that allows the coffee beans to be ground and packaged freshly roasted to guarantee fresh coffee.

Renewable Energy

For our business we use 100% clean, certified electric energy produced from renewable sources without CO2 emissions and without the consumption of natural resources. Thanks to Dolomiti Energia, one of the leading producers of electricity from renewable sources, we purchase certified renewable and local energy.